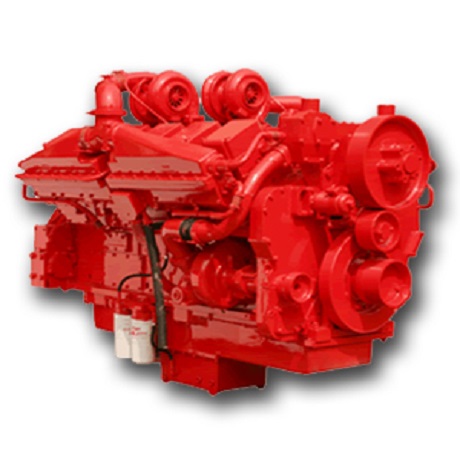

CUMMINS K SERIES

Maintaining their outstanding reputation for high performance power even in the harshest conditions,

the latest KTA range is jacket water aftercooled design. Its inbuilt step timing control system

ensures optimum engine timing at all combinations of load and ambient temperature, improving cold

starting and reducing light load fuel consumption to greatly enhance engine efficiency.

Wide range of applications: Since Cummins entered China in 1975, K19/38/50 series engines have been widely

used in construction machinery, heavy-duty vehicles, power generation, ship power and other fields;

forming strategic partnerships with important customers.

High reputation: As one of the main models of the Cummins family, K19/38/50 series engines have won high

recognition from customers in various fields with strong power, ultra-low fuel consumption, high

reliability and low maintenance costs.

Super power

Power covers 450-890 hp and maximum torque of 2586 Newton meters. Weight 1838 kg , the power weight

ratio.

Low fuel economy is good

Cummins PT fuel system patented technology, high injection pressure, ensure that the engine good

atomization, combustion.

Efficient Holset turbocharger exhaust intake ensures more fully , improve engine efficiency and

further improve combustion and reduce engine specific fuel consumption.

Air-to-air cooling technology ensures more sufficient air intake and better fuel economy.

Compact, easy to maintain

Replaceable wet cylinder liners , cooling effect , easy to replace.

All models parts versatility , high degree of serialization , and easy maintenance.

Block and head are taking a built-in pressure lubricants Road , compact , low failure rate

Advanced design and reliable performance

Cylinder block: made of high-strength alloy cast iron, with good rigidity, low vibration and low

noise.

Cylinder head: Four valves per cylinder design, optimized air/fuel mixture ratio, effectively

improving combustion and emissions; two cylinders and one head, easy maintenance.

Camshaft: The large-diameter camshaft can withstand higher loads. The new design can accurately

control the valve and injection timing. The optimized cam profile can reduce the impact force and

improve the reliability and durability.

Crankshaft: The integral crankshaft is made of high-strength forged steel. The induction hardening

process of fillet and journal can ensure higher fatigue strength of the crankshaft.

Piston: Using the latest aluminum alloy casting technology, the design of ω-shaped head and

barrel-shaped skirt can compensate for thermal expansion and contraction to ensure a good fit.

Product Model List:

NOT FIND YOU NEED?

There are more categories and models than what we show here. Please CONTACT US for querying more products.